Traction battery

Ultimate Guide to Traction Battery: Golf Cart & Forklift Battery Features

As a professional, it is important to have a thorough understanding of the features of lead-acid forklift batteries. These batteries are commonly used in a variety of industrial settings and should be maintained properly to ensure their longevity and maximum performance. One of the primary benefits of lead-acid batteries is their affordability compared to other battery types. They are also highly versatile and able to handle heavy loads. It is important to note, however, that lead-acid batteries require regular maintenance, including charging and water levels checks. With proper maintenance, they can provide dependable and long-lasting service for your equipment. Be sure to consult with a reputable supplier or manufacturer to find the best lead-acid battery for your specific needs.

Products

Traction battery

-

Use advanced scientific formula and production process to ensure longer battery life

-

Excellent cycle performance with excellent deep discharge capability

-

Excellent sealing structure to prevent leakage

-

Short-circuit avoidance function to minimize battery short circuit

| Item: | Traction battery | Capacity range: | 100AH-700AH |

| Min order: | 10 PCS | Operating temperature: | -35°C~65℃ |

| Battery cell: | Tubular | Product origin: | China |

| Grid: | Thick anticorrosive silver alloy | Electrolyte: | Acid |

| Apply to: | Forklift, Golfcart,AGV | Trademark: | OEM brand |

Categories

New Products

-

N180 12V180AH heavy duty battery manufacturer

Lead-Acid Battery -

N220 12V220AH heavy duty battery manufacturer

Lead-Acid Battery -

N200 12V200AH heavy duty battery manufacturer

Lead-Acid Battery -

N150 12V150AH heavy duty battery manufacturer

Lead-Acid Battery -

N120 12V120AH heavy duty battery manufacturer

Lead-Acid Battery

Professional traction battery manufacturer

Our company specializes in the production of premium-grade lead-acid batteries for various applications, including forklifts, golf carts, and AGV systems. We are committed to upholding the highest standards of quality and durability in the industry through the use of state-of-the-art technology and innovative manufacturing processes. Our batteries boast high-capacity and deep-cycle performance, ensuring reliable and long-lasting service life.

We focus on the quality

With over 28 years of experience to manufacturing lead-acid batteries, quality control always being our first mission

The company boasts advanced equipment for production, test and detection in the industry, and the productive process of lead-acid battery has passed the certification of IS09001 international quality management system, ISO14001 Environment Management System Certification, OHSAS18001 occupational health and safety management system, IATF16949 management system certification. In terms of its properties and functions, the products have reached and outperformed international standards such as JIS (Japan), BS (UK), DIN (Germany), IEC (International Electro Technical Commission), GB5008.1-92, GB5008-91, TB/G4282-92 and TB/T6457.2-92.

Excellent technical characteristics

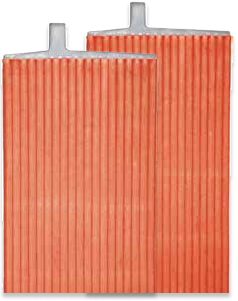

Advantages of tubular

Positive plates

-

Polyester gauntlets are fixed by acrylic resin.

-

Half of outside tubes are covered with additional resin to prevent side short circuits. >Tubular design keeps the active material mechanically together and presses it onto the grid and thus prevents shedding ofactive material due to forklift vibrations.

-

The tube with the circularcross section avoids shedding of the mass and keeps the struc ture together.

-

Corrosion speed is reduced by the tubesbecause pressing the PbO corrosion layer onto the grid surface and helps to protect the lead grid against further corrosion.

-

The tubular grid needs no horizontal bars,which reduces lead weight and avoids growing of the gri in the width.

-

The flat plate battery is typically 15% heavier than the tubular and consequently the flat plate battery bears higher costs.

-

Tubular plates could be produced by dry filling or wet-paste filing with uniform mass density.

-

For bridging times of 1h and longer, tubular plate batteries are more economical. >Tubular batteries have lower corrosion behavior due to the tubular design and also due to the different casting technique.

-

The tubular grids are casted with a 110-130 bar pressure unit,thus avoiding voids and cracks nearly completely.

-

Batteries with tubular plate design have excellent deep cycling performance. > Expected life is 20% higher as flat plate.

Outstanding impact

Resistance

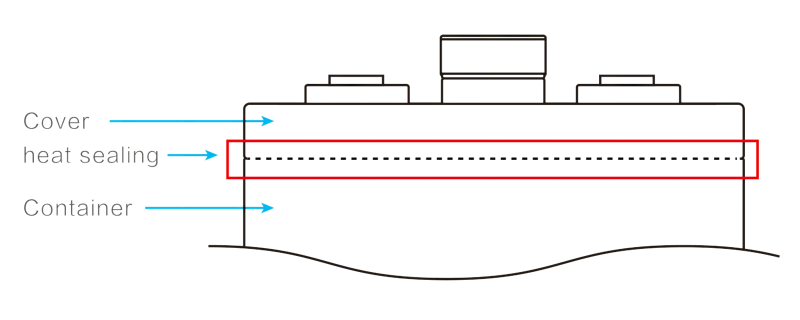

The container and the cover are made of synthetic resin which is ten times as rigrid as ebonite.The cover is sealed into one body with the container through heating method.

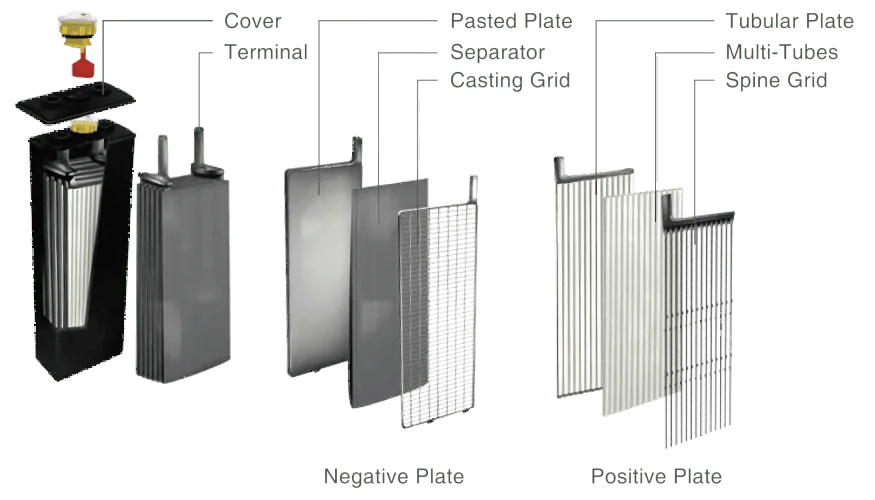

Positive plate design

Bottom bar(Exclusive)

-

Specially-designed bottom boot allows for positive plate growth during heavy use withoutloss of material

-

Tube is ultrasonically welded to bottom bar

-

Longer plastic piece on bottom bar allows for growth of positive spine into bottom bar'scavity during opportunity charging

-

Result is longer service life, especially when opportunity charged

Battery characteristics

Advantages

-

Use advanced scientific formula and production process to ensure longer battery life;

-

Excellent cycle performance with excellent deep discharge capability;

-

Excellent sealing structure to prevent leakage;

-

Short-circuit avoidance function to minimize battery short circuit.

Appropriate

Types

-

DIN -SERIES: DIN sizes, positive tubular plate diameter 8.7 mm,specific gravity of the electrolyte 1.29kg/l

-

BS-SERIES: BS sizes, positive tubular plate diameter 8.7 mm,specific gravity of the electrolyte 1.29kg/l

Traction battery

Structure

Battery Locomotive

Battery Forklift

AGV System

Electric Pallet Truck

Explosion-proof Battery Locomotive

Golf Cart

About traction battery

When it comes to material handling, having reliable equipment is paramount. This is why many industries have turned to lead acid forklift batteries to power their operations. These batteries have been tried and tested over many decades, proving their reliability and durability time and time again. In fact, it's hard to find a warehouse or factory that doesn't have at least one lead acid battery powering their forklifts. With their long lifespan and consistent power output, these batteries are a smart investment in the efficiency and productivity of your workplace. Additionally, with proper maintenance, your lead acid batteries can continue to provide reliable service for years to come. So, whether you're looking to replace your current forklift battery or you need to power new material handling equipment, choosing lead acid batteries is a choice you won't regret.

APPLICATIONS FOR